ISO 9001 Certified

Toll Free: 1.866.519.9674

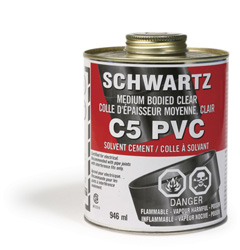

Plumbing - Solvent Cement - C5 Medium Bodied Clear PVC

- Product Description

- Physical Properties

- Application Data

- Directions for Use

- Print MSDS/TDS

Product Code:

10C5

Product Description and Uses:

The Schwartz C5 Clear PVC Cement is used for bonding PVC to PVC pipes for both Non-Pressure and Pressure applications.

Certification:

CSA certified for CPVC plastic pipe and fittings.

Certified to NSF/ANSI 61

Canada Green Building Council - Leed Compliant

Standard Container Sizes

60 ml Dauber

118 ml Dauber

236 ml Dauber

473 ml Dauber

946 ml Dauber

3.78 Litre Screw Top

Physical Properties:

Density: |

0.91 – 0.93 g/ml |

Weight Solids: |

14 - 16% |

Flashpoint: |

-17°C |

Hydrostatic Burst Strength: |

400 psi (23°C); 200 psi (82°C) per ASTM F 493 |

Appearance: |

Clear liquid |

Shelf Life: |

3 years unopened |

Environmental Information:

VOC: NA

Suggested Uses: |

For PVC to PVC for both non-pressure and pressure applications for pipes and fittings. |

Application Tools: |

Dauber or brush. |

Clean-up Solvent: |

VC100 |

Pot Life: |

NA |

Cementing Procedure:

- Cut pipe square

- Clean and bevel pipe

- Dry fit

- Use Schwartz VC180 Purple Primer for all pressure applications.

- Apply a wet even coat of Schwartz PVC Cement on full bond area of the fitting.

- Apply a wet even coat of Schwartz PVC Cement on full bond area of the pipe.

- Immediately insert the pipe into the fitting and give a quarter turn.

- Hold pipe for 30 seconds to prevent pull back.

- Carefully wipe off excess without disturbing joint.

- Allow joints to set at least 30 minutes before moving or shifting joints.

Refer to Schwartz Technical Bulletin - Solvent Welding Plastic Pipe and Fittings for detailed information.

Set Times:

Handle newly assembled joints carefully until cement has gone through its set period.

Recommended set time is temperature dependent:

- Minimum 30 minutes at 15ºC to 38ºC

- Minimum 1 hour at 7ºC to 15ºC

- Minimum 2 hours at 0ºC to 4ºC

Cure Times:

|

Test Pressures For Pipe Sizes 1⁄2" to 1-1⁄4" |

Test Pressures For Pipe Sizes 1-1⁄2" to 3" |

Test Pressures For Pipe Sizes 3-1⁄2" to 8" |

|||

Temperature Range During Cure Period |

Up to 180 psi |

Above 180 to 370 psi |

Up To 180 psi |

Above 180 To 315 psi |

Up To 180 psi |

Above 180 To 315 psi |

15°C - 38°C |

1 hr. |

6 hr |

2 hr. |

12 hr. |

8 hr. |

24 hr. |

4°C - 15°C |

2 hr. |

12 hr. |

4 hr. |

24 hr. |

16 hr. |

48 hr. |

Storage:

Store indoor at room temperature, away from heat, ignition sources, open flames and direct sunlight.

Warning:

Avoid open flames, turn off all pilot lights, ensure that work area is properly ventilated.

Soiled rags and waste products may contain combustible liquids or vapours and SPONTANEOUSLY COMBUST, dispose in accordance with local regulations.

Refer to MSDS for information on safe use of this product.

Material Safety and Technical Data Sheets for download.

Please click the appropriate link below.

TDS

TDS 10C5 - C5 Medium Bodied Clear PVC Solvent Cement (pdf)