Setting the Standards for

Predictive Maintenance

ISO 9001:2008

Certified

FS 67430

Vibration Analysis

- About Vibration Analysis

- Predictive Maintenance Programs

Vibration Analysis

Vibration Analysis has been a developing science since the 1940's, but has only been available to general industry for the last few decades. While many conditions can be diagnosed, the most common are:

- Unbalance

- Failing Bearings

- Lubrication Problems

- Misalignment

- Mechanical Looseness

- Belt/Drive Problems

The key to determining the root cause of a mechanical problem lies in the analysis of the vibration spectrum. Before a spectrum can be analyzed, the Analyst must know all of the various rotating speeds of the different components of the machine. This requires a stroboscopic inspection which isolates the speed of the part.

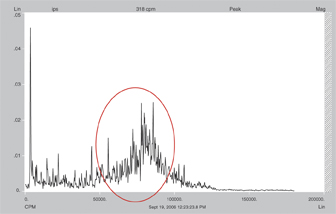

Once speeds are known, the Analyst takes a "spectrum" which breaks down and graphs the vibrations by severity (amplitude) vs frequency. When the Analyst can see that the problem is centered about a specific frequency and he knows what is turning at that frequency, he can quickly isolate the root cause of the failure.

Typical spectrum showing moderate bearing wear

Eliminating vibration leads to:

• Less Downtime

• Increased Productivity

• Improved Machine Reliability

• Lower Maintenance Costs

• Increased Bearing Life

• Extended Seal Life

• Longer Coupling Life

Click here to view a sample Vibration Condition Check Report.

Click here to download our Vibration Analysis Brochure.Predictive Maintenance Programs

For many Vibtech clients, the most powerful and cost effective approach to Vibration Analysis is through a Predictive Maintenance Program.

The Objectives of a Predictive Maintenance Program include:

- Control Downtime

- Increase Production

- Target Maintenance Efforts

- Enable Prioritized Repair Scheduling

- Reduce Damage to Equipment

- Lower Maintenance Costs

- Reduce Overtime

- Maximize Return on Maintenance Dollars

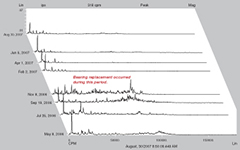

Under such a program, the severity of vibration readings becomes secondary to the rate of change … it is as important to know how a machine is changing over time as it is to know whether or not a given reading is over or under alarm points. For example, a machine's bearing vibrations may be in ranges which, by themselves, would indicate that it needs immediate replacing. However, when viewed over time, the vibration levels may be changing very slowly and the repair can be more conveniently scheduled. Conversely, readings which are barely in alarm may not seem to be of concern, but the rate of deterioration may indicate that replacement should be made immediately.

All successful Predictive Maintenance Programs have these critical elements:

- The frequency between checks must be adequate to facilitate prediction.

- All measurements must be captured and stored for reference and analysis.

- There must be some method of trending data.

- Reporting is specific about problems, and clearly indicates the corrective work that is required.

Our Predictive Maintenance Programs offer superior results because we:

- routinely collect more data per machine … resulting in more accurate analysis and diagnosis,

- use proprietary software to generate unique and detailed reports,

- report using specific comments, in plain language, detailing the work that is needed - with visual aids that highlight the most critical issues,

- provide useful summary reports for management.

- Click here to view a sample Start-up Report.

- Click here to view our standard Exception Report.

- Click here to view a sample Trending Report.

©2013 Vibtech Analysis Ltd. All rights reserved.

235 Industrial Parkway S., Unit 3B, Aurora, Ontario, L4G 3V5, Tel: 416-606-9999 (Toronto Line), Fax: 905-726-1115